HATCHecker When Hatch Cover Tightness Matters

Use HATCHecker to pinpoint the exact location of leaks in hatch covers. The HATCHChecker works with SDT’s ergonomic Flexible Sensor and the T-Sonic9 transmitter.

Sherlog MATE Function Kit for Hatchcovers Tightness Testing

Kozen use a totally new concept for hatch cover tightness testing.

For many years, leaking hatch covers have been vehicles for commercial disasters and even today claims for wet damaged cargo as resulting from leaking hatch covers remain one of the biggest concerns for ship owners, ship managers, cargo interests and their insurers. Owners, P&I Clubs and insurers are faced with several hundred million dollars of claims for wetting damage to cargo on a yearly basis, not counting consequences of wetting damage related problems such as delays, disruption of schedules and investigations.

Now ultrasonic tightness testing performed by Kozen can dramatically improve the n° 1 cause for claims each year – simply, accurately and reliably!

It has been proven that ultrasonic tightness testing of hatch covers with the SDT Sherlog can dramatically reduce exposure to claims filed against ships resulting from wet damaged cargo simply, accurately and reliably!

The Sherlog MATE kit includes the SDT200 receiver which is a high quality ultrasonic receiver which allows to easily identify areas where compression is affected and evaluate measurements which are shown digitally on the LCD display.

CARGO-SAFE™ Ultrasonic Hatch Cover Tester

Kozen is conscious of that the ingress of water through leaking hatch covers is a main cause of damage to cargo. It is in the interest of ship owners, managers and insurers to guarantee the cargo hold is watertight, as damaged cargo caused by water leaking through hatch covers often results in large claims against insurance companies and P&I clubs.

CARGO-SAFE™ is an ABS Type Approved hatch cover tester. The CARGO-SAFE™ UT tester in use of Kozen provides a quick and simple method of establishing weather tightness of hatch covers, bow, stern and side doors, but unlike hose testing, has no negative side effects on the port or harbour environment and can be performed in sub-zero temperatures.

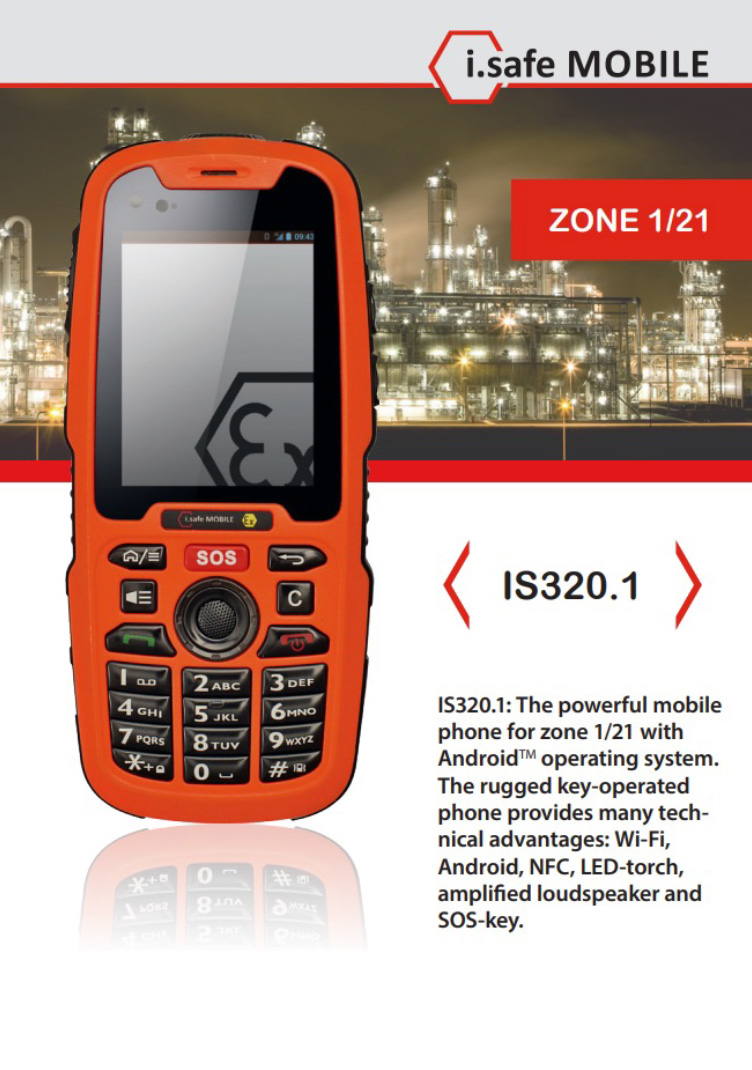

IS320.1 Android – 3G – ATEX Zone 1/21 – Camera

ATEX Zone is an IS320.1 Android explosion-proof camera. The ATEX ZONE in using Kozen is an ex-proof camera used to safely take photos from the open deck of tanker vessels.

Mobile Phone Zone 1/21 IS330.1

Mobile Phone Zone 1/21 IS330.1 is an Android explosion-proof camera. The Mobile Phone Zone 1/21 IS330.1 in using Kozen is an ex-proof camera used to safely take photos from the open deck of tanker vessels.

SKIPPER 5 MOISTURE METER – SMM5

Kozen utilizes Skipper 5 Technology for Moisture Detection

At Kozen, we employ advanced technologies to detect moisture and prevent structural issues in non-conductive materials such as GRP composites and hardwoods. As part of this approach, the Tramex Skipper 5 moisture meter is among the essential tools we use for the early detection of osmosis problems and effective intervention planning on marine vessels.

The Skipper 5 performs surface-contact measurements using high-frequency signals. Its ability to operate in both deep and shallow modes offers significant advantages in detecting hygroscopic salts within GRP structures—salts that are often responsible for moisture retention and osmotic cell formation. Thanks to its specialized electrode design, the device enables rapid scanning over large areas without causing damage to paints, varnishes, or coatings such as Cascover.

Kozen uses the Skipper 5 for the following purposes:

- Detecting moisture accumulation before the formation of osmosis

- Identifying wet core areas within sandwich or cored structures

- Monitoring hull drying before repairs or osmosis treatment

- Checking moisture levels in timber surfaces prior to painting, sheathing, or varnishing

- Locating and tracing leaks above and below deck

Kozen is equipped with Bluetooth functionality the Skipper 5 allows instant transmission of readings to mobile applications, speeding up field analysis and ensuring traceable data for reporting purposes.

Kozen continues to deliver high-quality maintenance and repair services to the maritime industry by using the most accurate diagnostic tools available.